The better a diamond is cut, the more it will reflect light and thus the more brilliant it will be.

The Size of a Diamond: Cut

The better a diamond is cut, the more it will reflect light and thus the more shiny it will be. The role of a diamond-cutter is crucial because, even with perfect colour and clarity, a diamond that is badly cut will never be as shiny as it could have been. On the other hand, if a diamond is well-cut, the lustre of a diamond will be increased.

The diamond-cutter begins with a specific test to determine which form to give and the way he will cut in order to obtain the biggest diamond(s) with the least possible impurities.

He then cuts the diamond following these 4 successive steps:

1. Cleavage

In this step the stone is cut. The first cut is made in the stone and a blade is inserted to split the raw diamond. It is at this stage that defects are eliminated, such as inclusions (impurities that have appeared on the diamond during cristallisation).

2. Sawing

A disk-shaped saw will allow for the diamond to be cut into many pieces.

3. Shaping

This gives the stone its round shape. This operation is made possible by the use of another diamond which is scraped against the stone to cut it.

4.Polishing

This creates the small flat surfaces that we call facets, thanks to a disk dipped in oil and diamond powder that is rubbed on the diamond.

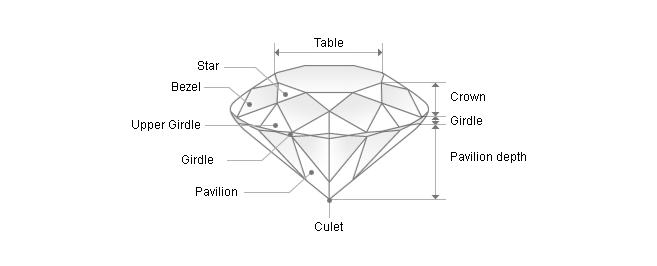

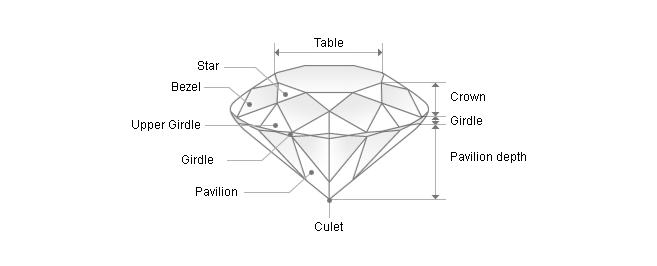

- The table : it's the biggest facet of the diamond

- The crown : the upper part of the diamond located above the girdle

- The girdle : the narrow band between the pavillion and the crown

- The pavilion : the lower part of the diamond located beneath the girdle

- The culet : the sharp point of the pavillion

- The chaton: the name of a facet located on the crown of the diamond

- The halefi : a facet located on the crown or the culet

- The star : facette in the shape of a triangle on the crown that separates the two girdles

- The pavillon : facette located on the culet

You will find diagrams below that simply explain the impact of the size on the lustre of a diamond:

.jpg)

The goal of a diamond-cutter is to cut the stone so that rays of light emanate from the top of the diamond, known as the crown, to maximise its lustre. He will also try to optimise what one calls the proportions of a diamond. The measurement device used for this is called a "Proportion scope". Beyond these proportions, the cutter also has to have an eye to optimise the finish, that is, the quality of the polish (the finishing of the stone's exterior) and its symmetry, which has an equally important impact on the lustre of the diamond. You will find an evaluation of these on your certificate :

- Excellent

- Very good

- Good

- Fair

- Poor

There are many ways to cut a diamond and thus many forms a diamond can take:

- Brillant cut

- Princess cut

- Emerald cut

- Asscher cut

- Oval cut

- Radiant cut

- Pear cut

- Heart cut

- Cushion cut

We owe the invention of the "brilliant" cut to Marcel Tolkowsky, who discovered the round form that allows for maximal sparkle of a diamond in 1919. It is the most widespread cut today, with 58 facets.

From an uncut to a cut diamond: 4 technical steps of the process

The diamond-cutter begins with a specific test to determine which form to give and the way he will cut in order to obtain the biggest diamond(s) with the least possible impurities.

He then cuts the diamond following these 4 successive steps:

1. Cleavage

In this step the stone is cut. The first cut is made in the stone and a blade is inserted to split the raw diamond. It is at this stage that defects are eliminated, such as inclusions (impurities that have appeared on the diamond during cristallisation).

2. Sawing

A disk-shaped saw will allow for the diamond to be cut into many pieces.

3. Shaping

This gives the stone its round shape. This operation is made possible by the use of another diamond which is scraped against the stone to cut it.

4.Polishing

This creates the small flat surfaces that we call facets, thanks to a disk dipped in oil and diamond powder that is rubbed on the diamond.

The composition of the final diamond

- The table : it's the biggest facet of the diamond

- The crown : the upper part of the diamond located above the girdle

- The girdle : the narrow band between the pavillion and the crown

- The pavilion : the lower part of the diamond located beneath the girdle

- The culet : the sharp point of the pavillion

- The chaton: the name of a facet located on the crown of the diamond

- The halefi : a facet located on the crown or the culet

- The star : facette in the shape of a triangle on the crown that separates the two girdles

- The pavillon : facette located on the culet

The brillance of a diamond

You will find diagrams below that simply explain the impact of the size on the lustre of a diamond:

.jpg)

The goal of a diamond-cutter is to cut the stone so that rays of light emanate from the top of the diamond, known as the crown, to maximise its lustre. He will also try to optimise what one calls the proportions of a diamond. The measurement device used for this is called a "Proportion scope". Beyond these proportions, the cutter also has to have an eye to optimise the finish, that is, the quality of the polish (the finishing of the stone's exterior) and its symmetry, which has an equally important impact on the lustre of the diamond. You will find an evaluation of these on your certificate :

- Excellent

- Very good

- Good

- Fair

- Poor

Shapes of diamond

There are many ways to cut a diamond and thus many forms a diamond can take:

- Brillant cut

- Princess cut

- Emerald cut

- Asscher cut

- Oval cut

- Radiant cut

- Pear cut

- Heart cut

- Cushion cut

We owe the invention of the "brilliant" cut to Marcel Tolkowsky, who discovered the round form that allows for maximal sparkle of a diamond in 1919. It is the most widespread cut today, with 58 facets.

Jewellery

for Everyone

for Everyone

Accessible, inclusive, and universal

EVERY MONTH, EDENLY GIVES AWAY

A PIECE OF JEWELLERY WORTH £500

A PIECE OF JEWELLERY WORTH £500

or refund of your jewellery up to £500. All subscribers to our newsletter and followers of edenly.jewellery on social media are automatically entered into the draw.

Your email will never be marketed. By validating, you agree to the Edenly Privacy Policy. +info

Congratulations Catherine S. (Maisons-laffitte ) !

This month, you win the Eclosion Nº5 earrings in 9-carat gold and diamonds.