Our expertise

DESIGN

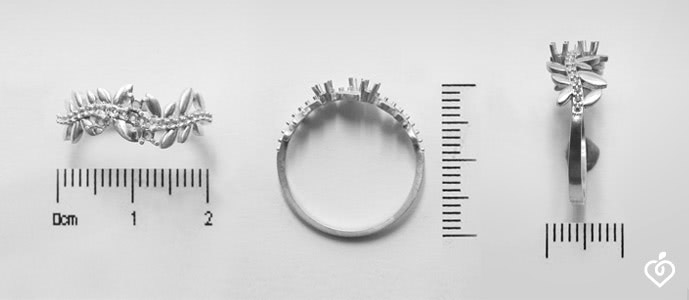

Our jewels are designed by Sarah Gaillard in Geneva. Every jewel is born in a drawn sketch and a prototype realised .

PRODUCTION OF THE PROTOTYPE

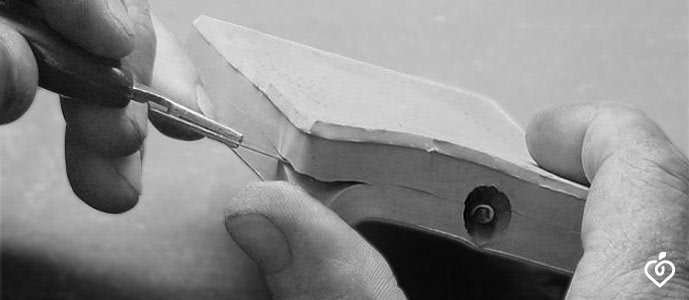

A prototype following the design is created by an artisan (jewellery without its stones). A rubber imprint is then carried out by means of vulcanisation. After cooling, the mould is cut to release the prototype. Thus, one is able to obtain a rubber imprint of the prototype. Next, liquid wax is injected inside the rubber mould in order to obtain an exact replica of the initial prototype after removal from the mould.

PLASTER MOULDING

The wax jewellery is then placed in a metal cylinder and surrounded with a coating (plaster resistant to heat).The set is then placed in an oven at a high temperature (about 750°C) to allow for the elimination of the wax (melted then burned) and to approach the temperature at which the mould melts. At this stage, one obtains a reverse imprint in plaster of the jewellery set.

PREPARATION OF THE ALLOY

The quantity of gold and other metals that compose the alloy for the jewellery is determined. According to French Law, we use an alloy of 18 carats which contains 75% gold. Pure gold being 24 carats, for 24g of alloy you have 18g of pure gold. The mix with other metals determines the color of the gold, whether it is yellow, white, or pink. As an example, pink gold consists of 75% pure gold, 12,5% silver and 12,5% bronze, which provides the best results for colour/mechanical properties.The gold alloy is now heated to nearly 1000°C. It is at this stage that it is injected into the plaster mould. After cooling, the plaster is dissolved in order to retrieve the "raw casting" pieces.

FINISHING

Our diamond jewellery maker will now manually rework the surface of the jewellery to give it its definitive appearance. The different parts of the jewel are assembled in their different colours, depending on the piece of gold diamond jewellery. At this stage, the form of your jewellery is complete.

SETTING

The stone is now adjusted on the jewellery for an optimal setting. It is then "fixed" with different techniques: prong settings, trail settings, invisible settings, etc. It is a long and delicate process that requires a great deal of patience and dexterity.

IMPRINTING THE SEALS

This operation consists of guaranteeing the origin and composition of your jewellery by imprinting two seals: - The "Seal of Guarantee" represented by the head of an eagle for 18 carats guarantees that your jewellery is composed of 75% gold. - The "Maître d'Ouvrage Seal" indicates the name of the jewellery manufacturer.

THE FINALIZATION OF YOUR JEWELLERY

The final lustre is now given to your jewellery. It is cleaned by ultrasound. Finally, your jewellery is carefully controlled for quality with a magnifying class to verify that all aspects of your jewellery are in order.

If this article interests you, you should also check out:

for Everyone

A PIECE OF JEWELLERY WORTH £500

Your email will never be marketed. By validating, you agree to the Edenly Privacy Policy. +info